News

2024.04.02

Columns

What is “Lacquerware”? Japanese Traditional Craft (Second Part)

Lacquerware (“Urushi” in Japanese) is one of Japan’s representative traditional crafts, and refers to products that are coated with lacquer. Due to its beauty and ease of use, it is popular overseas, and over time, many lacquerware products have been exported under the name “Japan.”

Continuing from the previous column, we will introduce lacquerware this time as well. This time, let’s take a look at the types of lacquerware products, the processing methods for lacquerware, and famous lacquerware production areas.

Table of Contents (Part 2)

*Click here for the first part

4. Lacquerware Products

_4-1. Variety of Lacquerware

_4-2. Compatibility Between Lacquer and Base Material

_4-3. Lacquerware Made of Synthetic Resin

5. How Lacquerware is Made

6. Representative Lacquerware Production Areas

7. Conclusion

Lacquerware Products

Variety of Lacquerware

In the first part, we introduced what lacquer is, how it is collected, and its characteristics. So, what kind of products are there that use lacquer, that is, lacquerware?

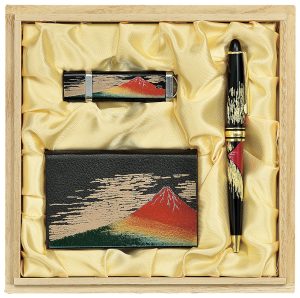

Lacquerware products are a wide variety of products. When most people think of representative lacquerware, they probably think of wooden bowls and trays. There also are lacquerware products such as chopsticks, spoons, jubako boxes, combs, handheld mirrors, desks, and chests of drawers. Lacquer was also sometimes used to decorate Buddhist statues and katana (swords).

_______

_______

Compatibility between Lacquer and Base Material

As you all know now, lacquer is a paint, so any product can be made into lacquerware by applying lacquer. However, not every material is suitable for applying lacquer; there are compatibility. It is easier to apply lacquer to materials that have a rough surface, or easily soaked by liquids, such as wood or paper are compatible with lacquer. Cloth, leather, and stone are also good material, because they have many small holes that allow it to penetrate.

If the surface is smooth and the liquid cannot penetrate, such as metal or glass, lacquer will peel off even if you apply lacquer as usual and let it dry. Therefore, a “high-temperature drying method” is used to bake the lacquer. Another method is to roughen the surface using a file to make it easier for the lacquer to adhere. Even if the material is not compatible, it is now possible to apply lacquer by adding some ingenuity, and the range of lacquerware products is expanding.

Lacquerware Made of Synthetic Resin

Recently, there are many lacquerware products that use synthetic resin (plastic) or wood mixed with synthetic resin and wood flour as the base, and chemical paint or lacquer mixed with chemical paint as the paint. Synthetic resin products are made by putting the material into a mold and hardening them, so they can be made into more flexible shapes than wooden products, and can be produced in large quantities at a lower cost. On the other hand, it is inferior to lacquerware, which is made of natural wood and coated with natural lacquer, in terms of heat retention, insulation, and ease of repair.

Both synthetic resin products and lacquerware made from natural materials each have different benefits. I think you should choose the one that suits your purpose and use it wisely.

How Lacquerware is Made

It takes a long time to create lacquerware using natural lacquer. For example, a lacquerware bowl is made as follows.

◎Wooden bowl making → Undercoating → Intermediate coating/Top coating → Decoration

1. Wooden Bowl Making

First, make the body (wood based) that will be coated with lacquer. In the case of wood bases made from natural wood, the wood is dried for about six months to a year, then carved using a potter’s wheel, or the pieces are cut and assembled.

2. Undercoat

To strengthen the wood, raw lacquer (filtered lacquer without any pigment mixed in) is applied to the entire surface of the wood using a brush or spatula, then dried and polished. This is a very important process that affects the strength and quality of the product.

3. Intermediate coating/Top coating

Paint, dry, and polish over and over again. Skilled technique is required to achieve a uniform thickness. The number of coats varies depending on the type of product and the craftsman’s preferences.

Unlike when drying things in general, lacquer dries quickly when the humidity is high, and slowly when the humidity is low. An environment with a humidity of 70-85% and a temperature of 20-30℃ is suitable for drying. Controlling temperature and humidity is important because the color appearance varies depending on the speed of drying. It takes more than 3 months from undercoating to topcoating.

4. Decoration

Finally, decorate the lacquerware. There are various ways to do this. “Makie” involves applying lacquer to a brush to draw a pattern, then adding gold or silver powder on it. “Chinkin” involves carving a pattern with a knife and then adhering gold leaf or gold powder to it with lacquer. “Raden” uses finely shaved shiny shells to create patterns. “Screen printing” involves placing ink on the surface of cloth. There are various other methods as well.

Representative Lacquerware Production Areas

Lacquerware is produced in various regions of Japan as shown below.

・Tsugaru lacquerware (Aomori)

・Kawatsura lacquerware (Akita)

・Naruko lacquerware (Miyagi)

・Aizu lacquerware (Fukushima)

・Edo lacquerware (Tokyo)

・Kiso lacquerware (Nagano)

・Murakami Tsuishu (Niigata)

・Takaoka lacquerware (Toyama)

・Wajima lacquerware (Ishikawa)

・Yamanaka Lacquerware (Ishikawa)

・Kanazawa lacquerware (Ishikawa)

・Echizen lacquerware (Fukui)

・Kishu lacquerware (Wakayama)

・Kagawa lacquerware (Kagawa)

・Miyazaki lacquerware (Miyazaki)

Famous production areas are concentrated in Tohoku area and Hokuriku area, but you can see that it is produced in various places from the north to the south in Japan. There are various characteristics depending on the production area, but we would like to introduce this on another occasion.

Conclusion

Lacquerware is a representative craft of Japan. It is produced all over Japan, and there are various types of products. Lacquerware made from natural wood and natural lacquer is made using traditional methods, using precious raw materials, and takes a long time and effort to complete.

In recent years, many lacquerware products have been produced using synthetic resin, which can be produced cheaply and in large quantities, and continue to evolve with the times to suit our modern lifestyles.

In this and the previous column, we introduced lacquerware. We would be happy if you could learn even a little bit about lacquerware and become interested in it.

Imoto Sangyo handles various types of ceramics, kitchenware, and daily necessities.

For more information, please see the “Goods & Cases” page.

(Reference)

Ministry of Agriculture, Forestry and Fisheries

Japan Urushi Ware Federation of Cooperatives

Wagokoro

Category

Archive